The Bio-scouring Enzymes of Innovative Application in the Dyeing Industry

The Bio-scouring Enzymes of Innovative Application

in the Dyeing Industry

By Baico Biotech | Textile Enzyme

In the current highly competitive textile dyeing and finishing industry, dyeing factories are increasingly demanding efficient, environmentally friendly and high-quality processing technologies. BBT produce the bio-scouring enzyme -- RF838-K, as a type of biological enzyme preparation, demonstrates great application potential in the dyeing factory production process due to its unique properties.

The operating principle of the RF838K

RF838K are not a single enzyme but a complex enzyme system consisting of multiple enzymes. In cotton fibers, pectin substances are an important component of the primary cell wall and intercellular layer. Bio-Scouring enzymes can specifically recognize and act on pectin molecules, removing the pectin on the surface of the cotton fibers, allowing the fibers to be fully swollen and separated. This improves the accessibility of the fibers and lays a good foundation for subsequent dyeing, finishing and other processes.

The Application of BBT RF838K in the Pre-treatment Process of the dyeing Factory

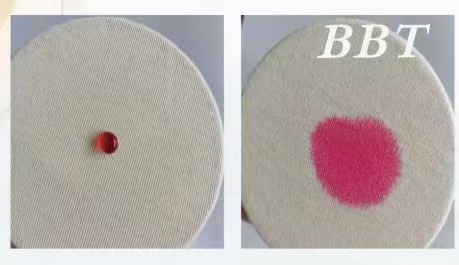

The traditional pre-treatment methods usually involve boiling with high temperature and strong alkali to remove impurities such as pectin and waxes from cotton fibers. However, this method is not only energy-intensive but also causes significant environmental pollution. Moreover, it may damage the fibers and affect the feel and strength of the fabric. By using BBT bio-scouring enzyme for pre-treatment, efficient impurity removal can be achieved under mild conditions. The fabric treated with bio-scouring enzyme shows a significant improvement in luster and absorbency. This provides a guarantee for the even dyeing of dyes during the subsequent dyeing process.

The improvement of dyeing quality by the BBT bio-scouring enzyme

A good pretreatment effect is the prerequisite for achieving high-quality dyeing. After being treated with bio-scouring enzyme, the surface of the fabric fibers becomes smoother and more uniform, and the gaps between the fibers increase. This enables the dye molecules to diffuse more smoothly into the interior of the fibers and form a firm bond with the fibers. During the reactive dyeing process, the dyeing depth of the fabric treated with bio-scouring enzyme significantly increases, the color becomes brighter and more saturated, and the color fastness is also significantly improved. Bio-scouring enzyme can reduce the amount of dye staff used during the dyeing process, while ensuring the dyeing quality, achieving a reduction in production costs and resource conservation.

The application of BBT RF838K in textile dyeing and finishing plants is an important direction for the development of textile dyeing and finishing technology. It brings about an increase in production efficiency, improvement in product quality, and reduction in environmental pressure to the dyeing and finishing plants. BBT has been specializing in the production of textile enzymes for 21 years, dedicated to helping dyeing and finishing plants achieve green, efficient and sustainable development.

#bio-scouring enzyme #BBT enzyme #good absorbency