CA-300, A CATALASE CAN PENETRATE INTO YARN TO WORK

【USAGE DATA】

PH: 6.0-7.5

Bath ratio: 1:4~ 1:10

Temp: 30℃~60℃

The best temp:40℃~55℃

Run time: 5~10 minutes.

【DOSAGE】

O.W.F(Depend On Weight Of Fabric)

| Fabric | Cotton% | Catalase CATANA® CA300 |

| Pure cotton/blended | ≥60 | 0.05% |

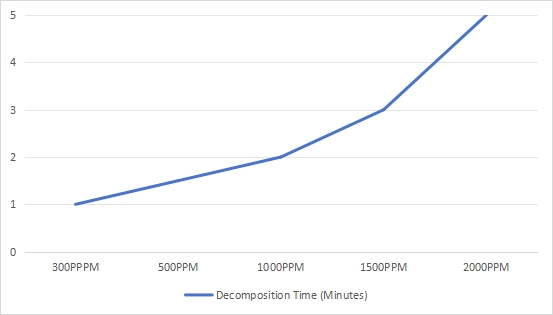

Decomposition time of Catalase CA300G at 300-2000 ppm hydrogen perixde

【PROCESSING】

1. After neutralization , Drain out the water.

2. Fill the new water in the dyeing machine . Adjust PH 6.5 -7.5 and increase temperature to40-55℃

3. Add catalase CATANA® CA300 and neutral cellulase NEF® 2100 in the attach tank. Run it more than 10 minutes then dyeing .After 50minutes check the bio-polishing performance. The one bath way of BBT to decompose hydrogen peroxide,bio-polishing and dyeing .

【 STORAGE 】

Keep it cool,ventilated, and the temperature should be less than 27℃. Avoid direct sunlight.

【 SAFE GUARDING 】

If irritation is noted, immediately flush eyes with a directed steam of water for at least 15

minutes, while forcible eyelids apart to ensure complete irrigation of all eye and lid tissue.